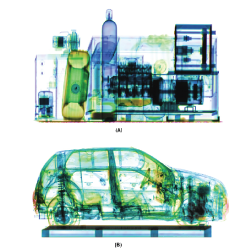

A complete vehicle inspection system is a technology which accurately inspects cargo and contents inside vehicles. It generally consists of X-ray scanners and hi-def cameras, which are installed on a moving tape. Most systems also include modern sensors such as those using semiconductor silicon chips to provide intelligence (that is to say processing capacity) as well as sensitivity. This enables it to detect anything dangerous or illegal hidden within the vehicle. This technology is widely employed now for security checks at airports, ports and customs posts.

Our Clients

Office Amenities

Place For Namaz

Place For Namaz Accepts Card Payment

Accepts Card Payment Bike Parking Facility

Bike Parking Facility Car Street Parking

Car Street Parking Lift / Elevetor

Lift / Elevetor Smoking Zone

Smoking Zone Wireless Internet

Wireless Internet

Full Vehicle X-ray System

Full vehicle cargo inspection system is the first of its kind in the world to employ cutting-edge x-ray technology for vehicle and load inspection. It offers superior penetrating X-ray imaging technology, capable of detection even large and thick materials with great accuracy. The advanced x-ray security inspection system for trucks, ships, and warehousing offers a quick and efficient method to detect security risks, ensuring stability in critical areas.

Accurate Material Discrimination

Advanced sensor and algorithm separation technology ensures that a complete truck scanning device can identify different types of materials. It also accurately analyzes the material and properties of objects so as to readily identify security risks or illegal materials. Therefore, every item is recognized separately.

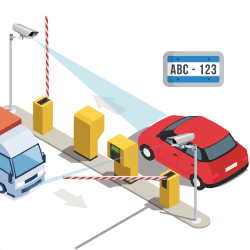

Automatic Numberplate Recognition

The number plate recognition technology of this system is able to automatically identify numbers, letters from a vehicle number plate. With the help of high-quality cameras and algorithms, it can recognize number plates Fastly and accurately, meanwhile catching all sorts of valuable information. In this way the technology aids security, guarantees the identity of vehicles and can also assist in taking criminals out of circulation. And it can hold all of its data.

Real-Time Data Processing

The complete cargo vehicle inspection system's data processing employs real-time technology to instantly analyze data from scans. It processes images and data instantaneously. This way, inspector screens the result of security test as soon appearing on their respective displays the system is designed to allow for fast decision-making and good security effect, especially in such busy port or border inspection areas.

Data Storage Details

In full vehicle cargo inspection system data storage details includes securely storing scanned images and texts. To do this, all data must be safely kept. The data can be acquired and analyzed at any time in the future--useful for monitoring and detection. That is how this ups its security level.

High Image Quality

This Cargo Full Vehicle Inspection System uses imaging technology of very high quality which provides extremely clear and detailed images. It has a high-resolution sensor that sees everything clearly. These technologies mean accurately what is inside the vehicle and cargo, and it is easy to identify potential hazards or abnormalities.

Professional Video Security

The video security system has undergone a comprehensive upgrade. Numerous advanced alarm management and precise zone intrusion detection techniques help to boost level of security; while adding features such as professionalism has expanded its functions. This enables security personnel to more effectively manage alarms and detect unauthorized access to specific areas; which means improved security and efficiency.

Automated Threat Detection

With a complete vehicle inspection system, all dangers are detected automatically. Advanced cameras and sensor technology are used to detect and find hidden hazards or dangerous materials within cargo itself. Automated alarms and warning characteristics quickly indicate suspicious occurrences that require the intervention of security personnel. This technology builds up security systems and helps quell dangers.

Robust and Durable Construction

Throughout the entire shipment vehicle inspection system, strong and stable materials are key. This system's components are made of high-quality metal and rust-resistant materials, promising long life. Place a weight over it, keep stability. And no, the problem with regular use and maintenance: stable construction also extends life cycle while maintaining safety standards–it works well over time.

Area of Use

Full vehicle cargo inspection system is used in various fields such as airport cargo scanner, ports, customs checkpoints and logistics centers. It helps ensure the safety of cargo, particularly identifying dangerous goods or drugs. This system allows guards to check cargo fast and accurately, so security will increase.

Product Special Features

- Material Discrimination

- Spectroscopic Radiation Detection And Identification

- OCR Container Identification

- Full-Vehicle Scanning - Bumper To Bumper, Including Occupants

- High Throughput - More Than 150 Vehicles Per Hour

- Fast Data Integration And Display

- Small Operating Space, No External Shielding

- Low Radiation Dose For Safety And Small Size

Product Specification

| Type of X Ray Source | Electron Induction Accelerator |

| Energy | 4 to 7.5 MeV |

| Operting Frequency | 400 Hertz |

| Steel Penetration | up to 330 mm |

| Radiation Protction | 200 mm thick lead can |

| Scattering Ange | 80 Degree |

| Control Method | RJ45 Network Communication |

| Collimator | Ultra narrow Slit Beam |

| Heat Dissipation Method | Air Conditioned Ventilation Duct |

Related Products

Anti Slip Car Stopper Wheel Chock Block Price in Bangladesh(10)

Anti Slip Car Stopper Wheel Chock Block Price in Bangladesh(10) Parking Security Convex Curved Mirror(28)

Parking Security Convex Curved Mirror(28) Folding Arm Car Parking Barrier Gate(2)

Folding Arm Car Parking Barrier Gate(2) Rubber Wall Corner Guard(19)

Rubber Wall Corner Guard(19) Multichannel Rubber Cable Protector Speed Breaker Price in Bangladesh(1)

Multichannel Rubber Cable Protector Speed Breaker Price in Bangladesh(1) One Way Parking Lot Spike Strip Tyre Killer Price in Bangladesh(1)

One Way Parking Lot Spike Strip Tyre Killer Price in Bangladesh(1) Parking Ticket Management System(1)

Parking Ticket Management System(1) Remote Controlled Push Switch Fence Arm Barrier Price in Bangladesh(1)

Remote Controlled Push Switch Fence Arm Barrier Price in Bangladesh(1) Rubber Speed Breaker(25)

Rubber Speed Breaker(25) Automatic Car Parking Barrier Gate System Price in Bangladesh(9)

Automatic Car Parking Barrier Gate System Price in Bangladesh(9) Under Vehicle Car Search Mirror with Flashlight Price in Bangladesh(6)

Under Vehicle Car Search Mirror with Flashlight Price in Bangladesh(6) Dual Side Ref Car Parking Wheel Stopper Price in Bangladesh(39)

Dual Side Ref Car Parking Wheel Stopper Price in Bangladesh(39)

Frequently asked questions and Answers

A entire cargo vehicle inspection system is a technology which accurately inspects cargo and contents inside vehicles. It generally consists of X-ray scanners and hi-def cameras, which are installed on a moving tape. Most systems also include modern sensors such as those using semiconductor silicon chips to provide intelligence (that is to say processing capacity) as well as sensitivity. This enables it to detect anything dangerous or illegal hidden within the vehicle. This is widely employed now for security checks at airport cargo scanner.

The full vehicle screening system uses a variety of technologies to accurately inspect the cargo inside the vehicle. It usually achieves this by:

Scanning: First the vehicle is put through the scanning unit. These units contain X-ray technology or other scanning equipment so as to take a picture of the entire inside of a car.

Image Analysis: After the scanner snaps off the images, those images are processed in advanced software. This software can detect hidden things or dangerous content.

Real-time Monitoring: Live cameras and sensors carry live video that flows to help security personnel quickly pinpoint the suspicious objects.

Alarm: If any abnormality or speculative object is found, the system gives an alarm and informs the security personnel.

In this manner the full vehicle cargo inspection system guarantees security and contributes to decreasing flows of contraband or dangerous goods.

The system mainly consists of three parts: X-ray scanner system, mobile cargo scanner and fixed scanner.

X-ray Scanner System: This system uses X-ray technology to examine goods inside the vehicle. X-ray beams assist in detecting any objects, weapons or dangerous cargo buried within. Normally it is built permanently at airports, ports or at customs checkpoints.

Mobile Cargo Scanner: In this type of system, a car or lorry acts as the scanning equipment driving about different places to investigate the cargo. Being portable and mobile, it has different uses the we can make according to circumstances.

Fixed Scanner Facility: This system is installed on a permanent basis at a fixed location and begins automatically scanning of vehicles as soon as they enter its area. Generally, it is used in high traffic or key security locations such as ports and airports. Each of these systems has its own benefits and areas of application, based on particular security requirements.

The capabilities of inspection systems vary according to the manufacturer and model. As a rule, these systems are capable of inspecting hundreds to thousands of vehicles per day.

X-ray Scanner System: This type of system can generally scan 20 to 30 vehicles per hour. Larger scanner systems with various in some cases up to 50-100 vehicles per hour.

Mobile Or Portable Scanner Systems: Mobile scanners are usually able to inspect 10-20 vehicles an hour, but this varies according to location and use conditions.

Fixed scanner systems: This type can usually scan 30-50 vehicles per hour Some highly qualified models go to more than 100 cars per hour. This capacity depends on the size of the system, its technology and where it is installed.

The Full Vehicle Cargo Inspection system is used mainly to ensure safety. Its applications are many. For Hazardous Material Detection: To detect hidden explosives, weapons or other hazardous materials located inside vehicles.

For anti-smuggling: To prevent contraband or illicit goods such as narcotics, contraband.

For security enhancement: As an aid in airport security; ground staff should go around the air-port (an important security-sensitive place).

For compliance with law enforcement and regulations: To ensure cargo inspection as laid down in various laws and directives. This system ensures safety, removes risks and helps ground staff arrive at the correct answers quickly.

Some of the main areas where a complete truck & cargo x-ray examining system ought to be used include

Airports: Used to ensure the safety of the airport and to detect dangerous goods.

Ports: To increase the security standards of cargo handling import-export prevent smuggling.

Custom Check post: Inspect vehicles entering the country,

Military Bases: To raise security and identify dangerous materials.

Large Logistics Centers: Ensure safe handling of goods, and check for any suspicious items. The system of container vehicle inspection system plays an important role in security, risk resistance, and whether these venues comply with regulations.

Scanner unit: It typically employs some form of X-ray scanner system which can take pictures of the inside of the vehicle.

Camera: High-resolution cameras take real-time video which helps identify suspicious objects.

Sensor: These sensors locate different kinds of dangerous or possibly untoward objects.

Data Analysis Software: Use advanced software to down-image processing and analysis of scan images or video, then identify the suspicious objects in it.

Alarm and warning system: If any suspicious object is found, full vehicle cargo inspection system gives an alarm or warning message.

Safety Enclosure: The scanning unit and other components are securely enclosed so that operation is safe and efficient. With all these components combined together in harmony, we make sure that not only the vehicles but also their drivers can stay safe.

The normal lifespan of the machine is 10 to 15 years. But the number may vary with how often it is used and maintained, environmentally. What is more, later models are becoming more technologically advanced all the time. As long as you maintenance regularly, make improvements, and use it correctly, this relocatable x ray container cargo scanner can still be serving you well 20 years from now. For most systems, manufacturers provide technical support and upgrades for a certain amount of time.

To get a Complete Vehicle Cargo Inspection System operational, there is a gestation period during which time must be taken to become familiar with and prepare it. This varies according to the type of system and where it is deployed. Usually it runs like this:

Getting Started: After startup, most systems need five to fifteen minutes to come to work life. This phase is used to prepare and initialize some of the system’s parts.

Scanning Preparation: X-ray scanners or other scanning units may need some additional time to switch to the mode of scanning. Usually this will be between five and ten minutes.

This timeframe may vary depending on the system technology, scope and installation method. As a general rule, a completely prepared and ready system will normally require up to 15 minutes in order to start work.

Generally, the steps to work a container truck checking system go like this. Ready,

Turn on the system: From the system panel or control board, start it. Depending on the system this will sometimes cause a series of prompts seen in the scroll window, on completion of which the system itself will automatically go into its preparation stage.

Park the Vehicle: Position your vehicle for work. Normally this would be a scanning track positive or a detection region soon after.

Scanning:

Initiate Scanning: Begin the scanning from the control panel. Some systems will start scanning automatically when a vehicle enters the scanning area.

Keep an eye on the scanning process: While the scanning is in progress, watch live imaging and information on a monitor or a personal computer screen.

Data Analysis:

Data To review: Part-Scan have-like rooms. The software reviews the images and numbers after scanning. When it detects anything that looks out of place (suspicious objects or materials with hazardous properties), an alert is raised through a WARNING.

Results Execution: The results are examined and agreements arrived at. If any suspicious objects are discovered, further inspection is to be made as necessary (securing of scene).

Legal System:

Decision-Making: If something suspicious is found, make appropriate provisions such as cargo examination or disposal.

Repair And Maintenance:

Regular inspection: System and machinery tests should be carried out regularly to maintain proper performance. When all these moves are carefully followed, the Whole Vehicle Cargo Inspection System can be run and give safe passage.

The size of a entire vehicle inspection system can vary depending on the components and type of system. In general, the size of these systems can be divided as follows:

Scanning Unit Size:

X-ray scanners: Generally, X-ray scanner systems are large, ranging from 10 to 20 meters in length. The width and height of the scanner unit can be 5 to 7 meters and 4 to 5 meters respectively. Large scanner systems are designed for trucks and other large vehicles.

Mobile or Portable Scanners: These full vehicle cargo inspection systems are installed in a truck or car. Its size can usually range from 7 to 12 meters in length, and it can be easily transported to different locations.

Scanning area:

Fixed Scanner: Fixed scanner systems usually require a fixed scanning track, which can be 10 to 20 meters in length and 5 to 7 meters in width. The scanning area may vary according to the length of the vehicle.

Mobile or portable scanner: It can be placed in different places and the size of the scanning area is movable.

Operating Station:

Control Panel: The operating control panel is usually placed in a room or desk, the size of which is usually 2 to 3 meters in length and 1 to 2 meters in width.

Monitoring and data processing unit: This unit is connected to the system and is usually located in a room, the size of which depends on the number and size of computers and monitors used.

This size can vary depending on different models and manufacturers, and customized systems are also made based on special requirements.

This system is developed by many countries around the world, such as the United States, where Smiths Detection and L3 Technologies operate, European countries such as Nuctech (Netherlands) and Fraunhofer (Germany) and China, such as Unitech. In addition, Israel and Japan also produce advanced systems. For Bangladesh, there is potential to build such a system, but it requires technical expertise, advanced materials, and large investments. It may be possible to develop this technology in Bangladesh through necessary research, technology training and infrastructure development.

Advantages of a complete vehicle cargo inspection system include:

Detection of Dangerous Materials: These systems are able to discover explosives, weapons, or any other hazardous material hidden in a vehicle, a minus either to the security services.

Anti-Smuggling: It detects illegal drugs and contraband goods, increasing the effectiveness of law authorities.

Automated Scanning: The vehicle scanning process is organized by computer management, so that checks are both quick and accurate.

Real-time monitoring: Gives out images and data of actual time from within the scan, those security officers can take actions promptly.

High Clarity: Using the most advanced modern equipment, we hope these systems are able to give images of detail at high-definition levels.

Convenient operation: Some systems may be mobile or portable, useable inexpensively in various locations.

Enhancing Security: For the benefit of all society, security must be strengthened at airports, ports, customs posts, and other verification points responsible for securing public safety.

These all bring about a continuous improvement in efficiency and security within the system, ensuring safety at crucial points.

Having stock or not and comparing to the world market, this products price can be up & down. But right now, The Full Vehicle Cargo Inspection System Starting Price is 15,00,000 Taka Price in Bangladesh. If you want to buy, the price can be up & down depending on the feature, specification and other customization.

Product Tags

Product Reviews

Read all reviewsMd Rakib

From Dhaka on 7th Jun, 2023Submit your review

Your email address will not be published. Required fields are markedAdd Images & Videos to your review

Allowed file types: jpg, gif, png,mp4,avi max total size of files: 100MB, max number of files: 8!