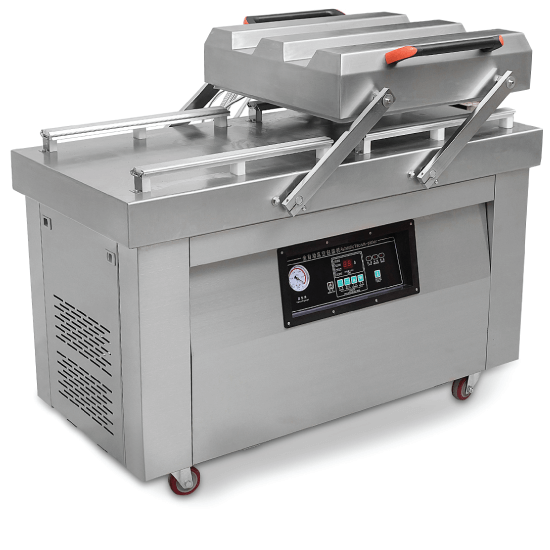

A vacuum packing sealing machine is an essential machine for the food/non-food packaging industries, especially for meat, seafood, and snacks. The air in the whole chamber, including air in the bags, is removed for best vacuum quality. The vacuum chamber sealer is made of real Stainless-steel material, thickness 4mm, so they are robust and don’t rust like as cheap machines. This machine has a wide application in food packaging industries, Hardware, chemical, textile products, etc. with high hygiene standards. So, you can find this Commercial Vacuum Packing Machine Near Me

Commercial Vacuum Packing Sealing Machine Price in Bangladesh

Product Spotlight

Boost your packaging performance with advanced Vacuum Packaging Machines designed for food and non-food industries. Built with SUS304 stainless steel body, powerful vacuum pump, and smart temperature control, it ensures hygienic, airtight sealing every time. Ideal for meat, seafood, snacks, and industrial products. Durable, efficient, and production-ready for commercial use in Bangladesh. Supplied by Nobarun International Since 2017.

Stainless Steel Body Material

Commercial Vacuum Packing Sealing Machine is one of the top technologies in food or non-food packaging and storage. The whole machine frame and surface are made of food-grade SUS304 stainless steel, easy cleaning, anti-corrosion, long-lasting. It’s designed for the small and medium-size production capacity of vacuum packing and sealing. Every chamber has two sealing strips. They are made of silicon.

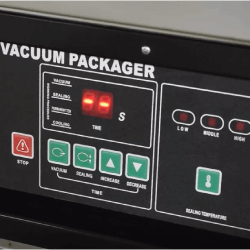

Independent Temperature Control

A wide range of sealing and heating temperatures makes this vacuum packing machine more suitable for production. After setting up the sealing temperature, putting the products into the chamber, we can get the vacuum products when temperatures reach some degree. There are three kinds of sealing temperature are optional, low temperature, middle temperature, and high temperature. For best packing quality, you are supposed to set up the right heating temperature. Each sealing bar’s temperature is controlled independently.

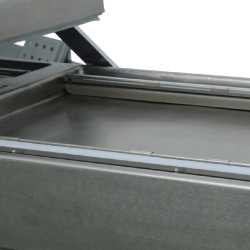

Chamber Details

Two types of vacuum sealing machines are available in the market. One is a single chamber vacuum packing sealing machine and the other one is a double chamber vacuum packing sealing machine. There are two vacuum rooms taking turns for vacuum packaging, working more efficiently than a single chamber vacuum packaging machine. The double chamber packing sealing machine has two vacuum chambers and a chamber lid for faster packaging speed. The chamber lid can be moved manually or automatically.

Smart Control Panel

This vacuum skin packaging machine has a smart water-proof control panel with an LCD screen display. This user-friendly control panel has an indicator light that will show you L/M/H according to low temperatures, medium temperatures, high temperatures. A vacuum meter, time setting display, 2 increase-decrease buttons, and a pump start button make this control panel smarter. It has an emergency stop button and a power switch too.

World Best Vacuum Pump

It has the world’s best vacuum pump which removes the molecules of air and other gases from the vacuum chamber. This commercial vacuum packing sealing machine is designed with a compact structure, lightweight, low noise, easy operation, and stable performance. This pump is equipped with a gas ballast valve to pump gas combined with a little water vapor. It can be used as a single pump and as a fore pump in a high vacuum system. With anti-oil-return device to guarantee a clean vacuum. It has a trouble-free service life. Can be operated at very low noise in the production environment.

Quick Cycle Time

This tabletop vacuum packing machine is designed with a compact structure. It’s a fully automatic packaging cycle. The noise is comparably low while operating. The time of an automatic packaging cycle can start from 10 seconds to 35 seconds. Shortly, it will take 1 minute for packaging 4 products.

Power Details

The meat packaging vacuum machine can be adjusted with local voltage and frequency. There will be no issues with electricity supplies. It’s a three-phase wire power supply with 2.2 KW. The frequency of this vacuum packer is 50 Hz. For avoiding compression and pulling, power cables should be rolled when not used.

Vacuum area

This ultimate Vacuum machine is limiting vacuum curving to prevent bacteria. The machine immediately seals after a vacuum to achieve the vacuum limit. This method inhibits the propagation of bacteria & avoids food spoilage. It is very convenient for food storage and transportation. This Vacuum sealer for food packaging machine uses German Schneider, OMRON, and other imported electrical applications to ensure the stability of product performance hundred percent.

Easy to Clean After Use

The vacuum sealing machine is on wheels so that it’s easy to move around. All the body and frame are made of 304 stainless steel which makes it an easy job for cleaning. This commercial vacuum packing sealing machine is generally used to seal fresh and raw food products, that’s why it requires regular cleaning. You just need a lightly damp cloth, water, and any kind of detergent. Don’t use a wet cloth because of electrical components appliance. Always unplug your machine before starting any cleaning process.

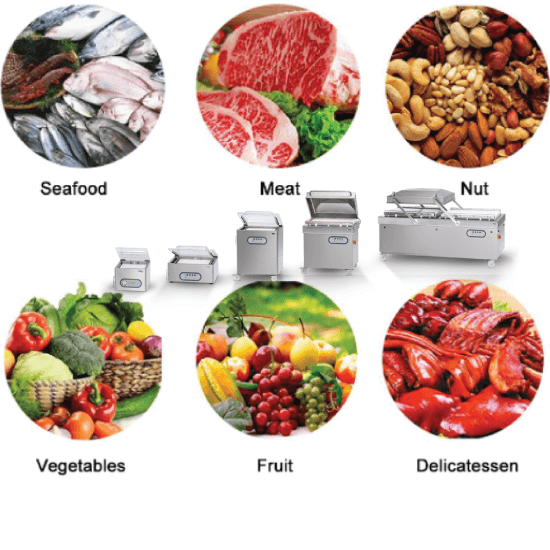

Wide Range Use

It has a wide range of applications. Commercial vacuum packaging sealing machine is widely used in food packaging solutions, especially for meat, seafood, and snacks, aquatic products, sauce products industry, the deep processing of vegetable industries, agricultural products, prepared food, medical instruments, electronics, and hardware factories, etc. After vacuum packing, products can be effectively be prevented from oxidization, insects, moisture.

Product Features & Benefits

- High Performance Vacuum Packaging

- Compact 13" Chamber Size

- Powerful 300W Motor Output

- Digital Touch Control Panel

- Automatic & Manual Operation

- 300mm Strong Seal Width

- Durable Stainless Steel Body

- 0.6–0.8 Bar Vacuum Pressure

Lightweight 4 Kg Tabletop Design - Ideal For Food & Retail Use

Product Specification

Length | 13" / 330mm / 33cm |

Width | 12" / 305mm / 30.5cm |

Height | 2" / 50mm / 5cm |

Brand/Model | DZ300T |

Material | Stainless Steel |

Power | 300W |

Voltage/Frequency | 220V / 50Hz |

Sealing Width | 11.8" / 300mm / 30cm |

Working Pressure | 0.6–0.8 bar |

Operation Mode | Auto & Manual |

Type | Table Top |

Weight | 4 Kg |

Compact Design | Retail Friendly |

Application | Food Packaging |

Origin | China |

Related Products

Cattle Skin Remover Dehiding Machine(1)

Cattle Skin Remover Dehiding Machine(1) Cattle Bleeding Shackle with Hanger(1)

Cattle Bleeding Shackle with Hanger(1) Meat Hanging Overhead Rail System(1)

Meat Hanging Overhead Rail System(1) Cattle Carcass Lifting Hoist Machine(1)

Cattle Carcass Lifting Hoist Machine(1) Cattle Marker Ear Tag(1)

Cattle Marker Ear Tag(1) Meat Hanging Transportation Trolley(1)

Meat Hanging Transportation Trolley(1) Pneumatic Lifting Platform Elevator(1)

Pneumatic Lifting Platform Elevator(1) Electric Cattle Splitting Saw Machine(1)

Electric Cattle Splitting Saw Machine(1) Halal Slaughter Cattle Killing Box Machine(2)

Halal Slaughter Cattle Killing Box Machine(2) Cattle Carcass Pulley Hook(1)

Cattle Carcass Pulley Hook(1) Livestock Cattle Weighing Scale Platform Price in Bangladesh(1)

Livestock Cattle Weighing Scale Platform Price in Bangladesh(1) Commercial Meat Slicer Machine(1)

Commercial Meat Slicer Machine(1) Commercial Ice Crusher Machine Price in Bangladesh(1)

Commercial Ice Crusher Machine Price in Bangladesh(1) Cattle Breastbone Saw Machine(1)

Cattle Breastbone Saw Machine(1) Overhead Static Monorail Weight Scale(1)

Overhead Static Monorail Weight Scale(1) Commercial Blast Freezer(1)

Commercial Blast Freezer(1) Commercial Cold Room Freezer(2)

Commercial Cold Room Freezer(2) Auto Temperature Control Ice Cream Display Freezer(1)

Auto Temperature Control Ice Cream Display Freezer(1) Commercial Frozen Island Display Freezer Price in Bangladesh(1)

Commercial Frozen Island Display Freezer Price in Bangladesh(1) (0 to -18º) Commercial Solid Door Upright Freezer(4)

(0 to -18º) Commercial Solid Door Upright Freezer(4) Commercial Cold Room Chiller(1)

Commercial Cold Room Chiller(1) Fruits and Vegetables Display Chiller Price in Bangladesh(1)

Fruits and Vegetables Display Chiller Price in Bangladesh(1) Commercial Meat Display Chiller(3)

Commercial Meat Display Chiller(3) Fresh Milk Cooling Tank Chiller(2)

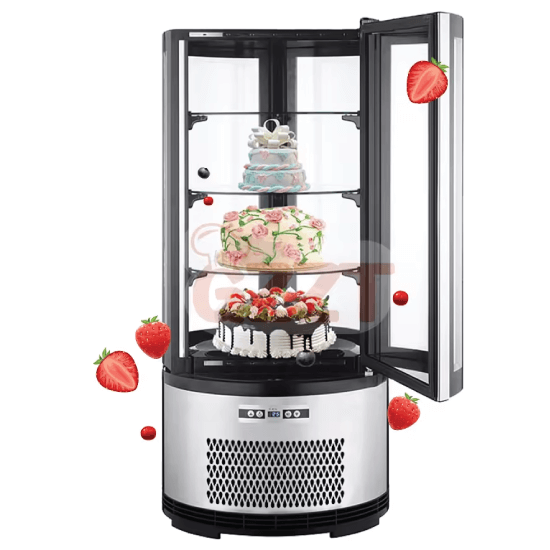

Fresh Milk Cooling Tank Chiller(2) "ROKADI" Rotating Cake Display Chiller(18)

"ROKADI" Rotating Cake Display Chiller(18)

Frequently asked questions and Answers

A single chamber vacuum machine is suitable for both home and commercial applications. This desktop machine contains small volume, lightweight, low energy consumption.

The double chamber vacuum machine is designed for medium and large-scale food or non-food product packing production. It has 2 working chambers and 1 swingable chamber cover. It features high packaging production output by working alternatively in the swinging chamber. When one vacuum room is closed, the other one can be prepared for vacuum packaging. So, the duel chambers work in turn improves packaging efficiency by 50% more than a single chamber vacuum machine. When working in big industries with large quantities of products, a double chamber machine is indispensable.

The main parts of the commercial vacuum packing sealing machine are chamber lid, Handles, vacuum pump (it can be a bush or china brand), LCD control panel, Emergency stop button, SUS34 frame, Silicon strips, 4 wheels, and connecting rod.

When working in catering industries with large quantities of products, a vacuum skin packaging machine is essential. The purpose of this packaging machine is to vacuum and seal food & non-food products with laminated plastic bags or aluminum foil bags.

Yes. This commercial plastic bag vacuum sealing machine is able to print date information. There are a bunch of small numbers of molds (0 to 9).

Products you can pack and seal with this robust machine:

1. Meat products including fresh, frozen, ground, bacon, burgers, cured meat products, etc.

2. Seafood and fish,

3. Pickled vegetables, dried fruits,

4. Cheese products (except soft cheese),

5. Non-food products (Medical/ Electronics/hardware etc.)

The sealing bar of this tabletop vacuum packing machine is 12 inches. There can be different sizes of sealing bars. Available in our stock.

It’s not suitable for the home. We have another machine which is home friendly. You will not regret it if you Buy a mini vacuum packing machine from us.

The size of a double chamber packing sealing machine is 57 inches * 29 inches * 37 inches.

The size of a double chamber packing sealing machine is 20 inches * 21 inches * 41 inches.

The power for a single chamber vacuum machine is 0.9 KW. and

double chamber vacuum machine is 2.2 KW.

No, this anti-spoiling Vacuum sealer for food packaging is not an automatic machine. It’s a semi-automatic machine.

The weight of the vacuum sealing machine is 150 kg.

The electrical specification of this machine:

380 voltage, 50 Hz, 3 phases.

So, it looks like the answer is YES. You can find this type of Commercial Vacuum Packing Machine Near Me.

None of this. It’s actually 380 voltage.

The answer is absolute no. Yes, it’s very useful to keep your foods healthy but not all food can be vacuum-packed. Fresh vegetables and fruits can’t be vacuum packed directly, you need to process them firstly, by drying, balancing. Some foodstuffs contain anaerobic bacteria, which can grow without the presence of air. It may have a risk to your health. So the row mushrooms, garlic, fresh corn kernels, sunflower seeds, soft cheeses are not suitable to vacuum. Any food that is still at a hot temperature that also prohibited to vacuum.

1. Confirm the power supply voltage and frequency used by the machine. It can save you from errors.

2. Please do not use this machine in a dusty environment.

3. When the machine is not used, the power should be cut off.

4. Replace the vacuum pump oil in time.

5. It must be confirmed that the vacuum pump has been filled with 2/3 of the vacuum pump oil.

6. Keep the inside and outside of the commercial vacuum packing sealing machine clean regularly.

7. Keep the instruction guide in a safe place.

You can use laminated vacuum bags or aluminum foil bags for this plastic bag vacuum sealing machine.

If you referring to a piece of meat that has been previously frozen and then vacuumed sealed then it will work.

What are the requirements of the installation environment for this machine?

Before using the vacuum packing machine, be sure to read the manual carefully and fully understand it.

1. Install the machine at a safe temperature. 5-30 degrees Celsius is the safe temperature.

2. Install the machine at standard atmospheric pressure.

3. Professional vacuum packing sealing machine must be kept upright when moving around or transporting.

4. Placed the machine on the level ground. It’s one of the elements of trouble-free operation.

5. Make sure there is enough space to change the vacuum pump oil.

The chamber might be deep enough to do small chicken or duck. So, I don’t think so. It’s for meat cuts and similar.

It has a powerful exhaust to ensure the normal use of the machine to extend machine life.

In a single-chamber vacuum machine, it has a double seal line. The double chamber vacuum packaging machine has two vacuum rooms. Every room has a double seal line.

1. Connect the power supply.

2. Turn on the power switch.

3. Set the sealing temperature and sealing time.

4. Keep the product on a sealing strip.

5. Press down the vacuum cover and began to vacuum.

6. When reached a certain period of vacuum degrees, then it began the sealing procedure.

7. After sealing, it enters the cooling condition and deflates.

8. The Whole packaging is completed.

9. Turn off the machine while packaging and sealing are completed.

1. Space Saving. Vacuum sealers can save your valuable time.

2. Our commercial vacuum packing sealing machine preserves food by preventing the growth of mold or bacteria. No chemical preservatives are required.

3. Vacuum sealing protects your food from dehydration and freezer burn.

4. Reduced product loss, the same weight you pack and the same weight you sell.

5. Quick and efficient packaging.

6. Frozen food that is vacuum sealed lasts an average of 2-3 years.

7. Vacuum sealing can maintain food’s freshness and original flavor.

8. Vacuum sealer can save your money.

9. Allow saving in quantity buying, you may buy products in bulk at a low price. Prepacked and sell later.

10. Prevent electronic and hardware parts from oxidization.

It works no matter the temperature with ZERO performance issues.

Dry food- 6 months to 24 months

Frozen food- Up to 36 months

Cooked food-3 Days to 14 Days

Raw Food- 2 week to 40 days

Having stock or not and comparing to the world market, this products price can be up & down. But right now, The Commercial Vacuum Packing Machine Starting Cost is 70,000 Taka Price in Bangladesh. If you want to buy, the price can be up & down depending on the feature, specification and other customization.

Product Reviews

Read all reviewsEstiq Ahmed

From Dutch Dairy Ltd on 8th Mar, 2022Very well product

Submit your review

Your email address will not be published. Required fields are markedAdd Images & Videos to your review

Allowed file types: jpg, gif, png,mp4,avi max total size of files: 100MB, max number of files: 8!