Our Clients

H#199 (1st Floor), R#01 New DOHS Mohakhali Dhaka-1206,Bangladesh

Product Spotlight

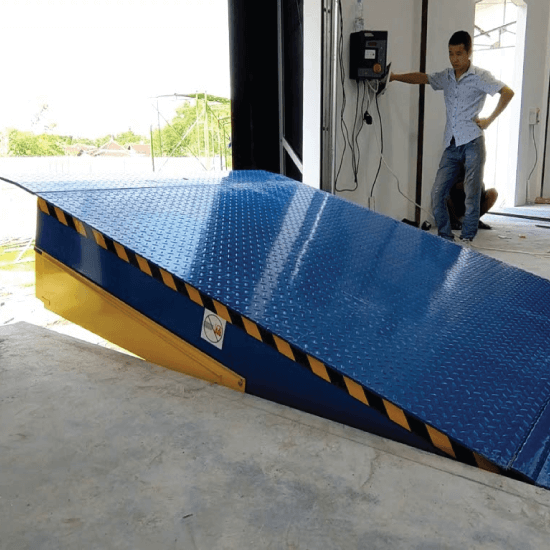

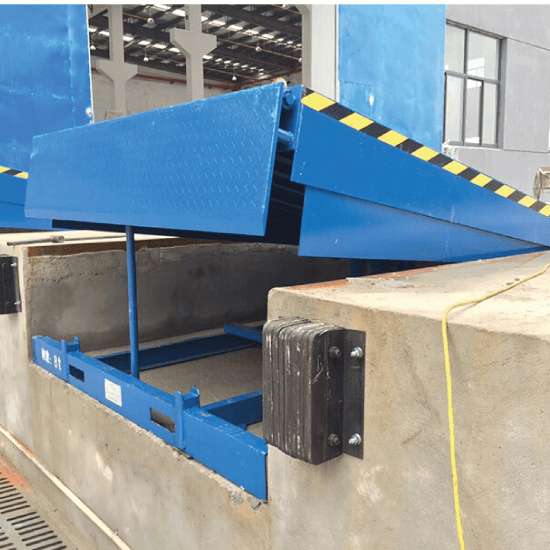

Industrial Automatic Hydraulic Loading Dock Leveler ensures safe and smooth loading between warehouse floor and truck bed. Built with heavy-duty steel platform and powerful hydraulic system, it adjusts automatically to different truck heights for fast and efficient operation. Ideal for factories, warehouses, and logistics hubs, it improves safety, reduces damage, and boosts productivity. By Nobarun International, trusted since 2017

Why Use Industrial Automatic Hydraulic Loading Dock Leveler

If you run a warehouse, factory, or distribution center, you already know how important loading and unloading work is. Every day, trucks come and go. Goods move in and out. Time matters. Safety matters even more. This is where an Industrial Automatic Hydraulic Loading Dock Leveler becomes very important.

Many businesses lose time and money because of poor loading systems. Sometimes the truck height does not match the warehouse floor. Workers struggle to move goods. Forklifts shake. Products get damaged. Accidents happen. A dock leveler solves all these problems in a simple and smart way.

Let’s understand everything clearly.

What Is an Industrial Automatic Hydraulic Loading Dock Leveler?

An Industrial Automatic Hydraulic Loading Dock Leveler is a heavy-duty platform installed at a warehouse loading dock. Its job is simple. It creates a smooth bridge between the warehouse floor and the truck bed.

Trucks come in different sizes. Some are higher. Some are lower. The dock leveler adjusts automatically using a hydraulic system. It goes up or down to match the truck height. This allows forklifts and workers to move goods safely and smoothly.

It works using hydraulic power. With just one button, the platform lifts and locks into position.

No manual pushing. No risky adjustments.

Why Is It Important for Industrial Use?

In industrial areas, work never stops. Large trucks carry heavy materials. Time pressure is high. Safety risks are real.

Without a dock leveler:

• Workers may use wooden planks

• Forklifts may tilt dangerously

• Goods may fall during loading

• Employees may get injured

An automatic hydraulic dock leveler removes these risks.

It keeps operations smooth and professional. It also increases productivity because loading becomes faster and easier.

How Does It Work?

The working process is very simple.

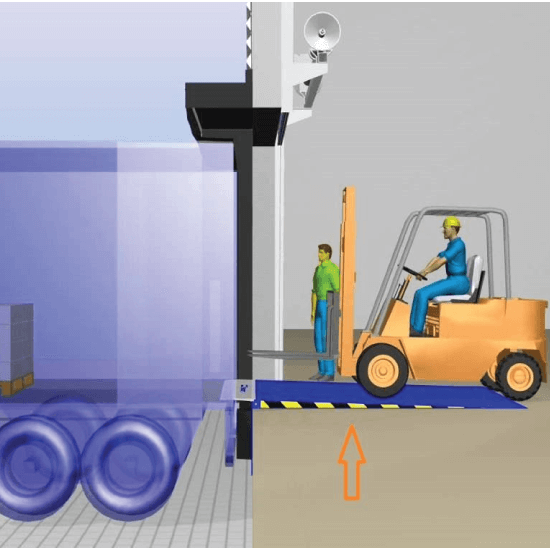

1. A truck parks at the dock.

2. The operator presses a control button.

3. The hydraulic system lifts the platform.

4. The lip extends and rests on the truck bed.

5. Loading or unloading starts.

6. After work, the platform returns to its original position.

Everything happens smoothly. No heavy lifting is required by workers.

The hydraulic system does all the hard work.

Main Components of the Dock Leveler

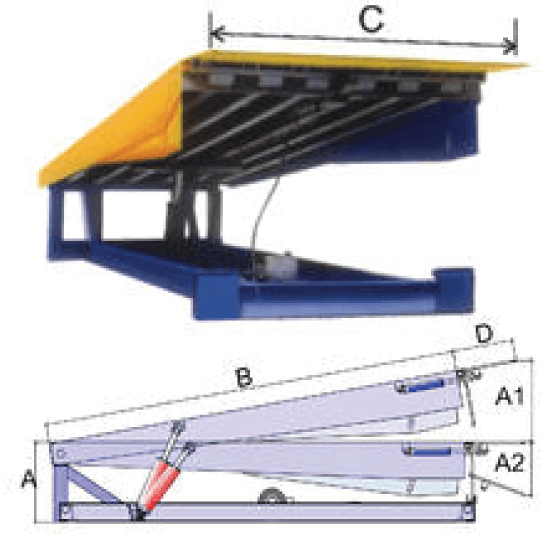

To understand better, let’s look at the main parts:

1. Platform

This is the main steel plate where forklifts move. It is made of heavy-duty steel to carry high weight.

2. Hydraulic Cylinder

This is the power system. It lifts and lowers the platform.

3. Lip Plate

The lip connects the dock to the truck. It extends automatically.

4. Control Panel

Used to operate the system with a simple button.

5. Safety Mechanism

Includes safety valves and emergency stop options.

Each part is designed for durability and heavy industrial use.

Benefits of Using Industrial Automatic Hydraulic Loading Dock Leveler

Let’s talk about the real benefits.

1. Improved Safety

Safety is the biggest advantage.

The leveler removes height gaps between truck and warehouse. Forklifts move smoothly without sudden drops. This reduces accidents and injuries.

Workers feel safer. Managers feel confident.

2. Faster Loading and Unloading

Time is money in industrial business.

With an automatic system, trucks are loaded faster. No need to manually adjust ramps. This increases daily output.

More trucks handled. More business done.

3. Heavy Load Capacity

Industrial dock levelers are built strong.

They can handle heavy forklifts and loaded pallets. Some models support several tons of weight. That makes them perfect for factories, warehouses, and logistics hubs.

4. Long-Term Durability

These systems are made of thick steel with anti-rust coating. They are built to last many years.

Once installed, they require very little maintenance.

5. Professional Image

When clients visit your facility, they see modern equipment. A proper dock leveler gives a professional and organized impression.

It shows that your business takes safety and efficiency seriously.

Where Is It Used?

Industrial Automatic Hydraulic Loading Dock Leveler is widely used in:

• Manufacturing factories

• Warehouses

• Distribution centers

• Cold storage facilities

• Logistics companies

• Export-import businesses

• Food processing plants

• Pharmaceutical factories

• Retail supply centers

Anywhere goods move by truck, a dock leveler is useful.

Types of Hydraulic Dock Levelers

There are mainly two types:

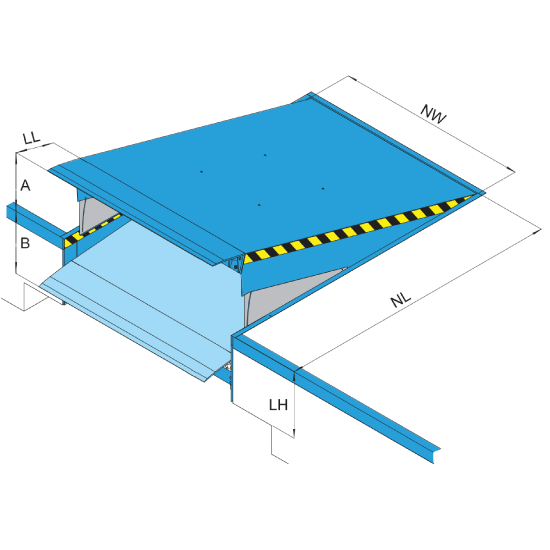

1. Pit Type Dock Leveler

Installed inside a concrete pit. Most common in industrial settings.

2. Edge of Dock Leveler

Installed at the edge of the dock. Suitable for lighter operations.

Industrial use mostly prefers pit type because it supports heavier loads.

Installation Process

Installation should be done by professionals.

First, a concrete pit is prepared according to size. Then the dock leveler frame is fixed into the pit. Electrical and hydraulic connections are done. Finally, testing is completed before use.

Proper installation ensures long life and smooth operation.

Maintenance Requirements

The good news is, maintenance is simple.

• Check hydraulic oil level regularly

• Clean dirt and debris

• Inspect moving parts

• Test safety system occasionally

That’s it.

No complicated servicing needed.

Things to Consider Before Buying

Before purchasing, consider these factors:

1. Load Capacity

Choose according to forklift weight and goods weight.

2. Platform Size

Make sure it matches your dock size.

3. Working Frequency

High traffic warehouses need heavy-duty models.

4. Weather Conditions

Outdoor use may require weather protection.

5. Power Supply

Ensure proper electrical setup.

Choosing the right model saves money and future problems.

Why Choose Hydraulic Instead of Mechanical?

Mechanical dock levelers require manual operation. Workers must pull chains and push platforms. This can be tiring and unsafe.

Hydraulic systems are automatic.

One button operation.

Less physical effort.

More safety.

Better control.

For industrial use, hydraulic is the smarter choice.

Energy Consumption

Many people worry about electricity use.

Hydraulic dock levelers consume power only during lifting. Once positioned, they do not use continuous power.

This makes them energy efficient and cost effective.

Weather Resistance

Industrial models are designed to work in tough conditions.

They can operate in hot, humid, or dusty environments. With proper coating and sealing, they last long even in challenging climates.

Common Problems Without Dock Leveler

Let’s imagine a warehouse without one:

• Forklifts struggle at height differences

• Workers use unsafe temporary ramps

• Loading takes longer

• More product damage

• Higher accident risk

Now imagine with a dock leveler:

• Smooth entry and exit

• Faster operations

• Safe workplace

• Professional environment

The difference is clear.

Return on Investment

Although it requires initial investment, it saves money in the long run.

• Fewer accidents

• Less product damage

• Faster truck turnaround

• Lower labor strain

• Increased productivity

Most businesses recover the cost within a short time due to operational efficiency.

Final Thoughts

An Industrial Automatic Hydraulic Loading Dock Leveler is not just equipment. It is a smart investment for any serious industrial business.

It improves safety.

It increases speed.

It reduces risk.

It makes work easier.

If your warehouse or factory handles truck-based loading daily, this system is almost essential.

Modern businesses need modern solutions. And this is one of the most practical upgrades you can make.

Product Features & Benefits

- Heavy-Duty Steel Platform

- Fully Automatic Operation

- Smooth Hydraulic Lifting

- High Load Capacity

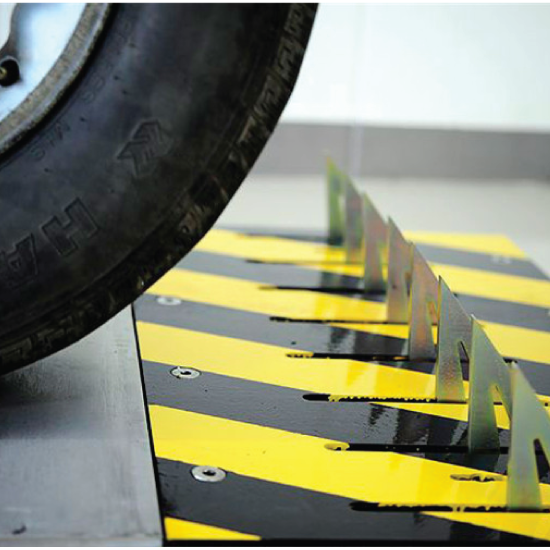

- Safe Anti-Slip Surface

- Fast Truck Alignment

- Energy Efficient System

- Low Maintenance Design

- Weather Resistant Structure

- Ideal For Warehouses

Related Products

Anti Slip Car Stopper Wheel Chock Block(10)

Anti Slip Car Stopper Wheel Chock Block(10) Parking Security Convex Curved Mirror(28)

Parking Security Convex Curved Mirror(28) Folding Arm Car Parking Barrier Gate(2)

Folding Arm Car Parking Barrier Gate(2) Rubber Wall Corner Guard(19)

Rubber Wall Corner Guard(19) Multichannel Rubber Cable Protector Speed Breaker(1)

Multichannel Rubber Cable Protector Speed Breaker(1) One Way Parking Lot Spike Strip Tyre Killer(1)

One Way Parking Lot Spike Strip Tyre Killer(1) Parking Ticket Management System(1)

Parking Ticket Management System(1) Remote Controlled Push Switch Fence Arm Barrier(1)

Remote Controlled Push Switch Fence Arm Barrier(1) Rubber Speed Breaker(25)

Rubber Speed Breaker(25) Automatic Car Parking Barrier Gate System(9)

Automatic Car Parking Barrier Gate System(9) Under Vehicle Car Search Mirror with Flashlight(6)

Under Vehicle Car Search Mirror with Flashlight(6) Dual Side Ref Car Parking Wheel Stopper(39)

Dual Side Ref Car Parking Wheel Stopper(39) Espresso Coffee Machine Foam Steamer Wand Price in Bangladesh(1)

Espresso Coffee Machine Foam Steamer Wand Price in Bangladesh(1) Remote Control Electric Swing Gate Opener(3)

Remote Control Electric Swing Gate Opener(3) Fire Rated Rolling Shutter(2)

Fire Rated Rolling Shutter(2) Walkway Flap Barrier Gate(1)

Walkway Flap Barrier Gate(1) Crowd Control Stanchions Belt Barrier With Rope(1)

Crowd Control Stanchions Belt Barrier With Rope(1) Automatic Remote Control Sliding Gate Opener System(1)

Automatic Remote Control Sliding Gate Opener System(1) Full Height Turnstile Gate Barrier(1)

Full Height Turnstile Gate Barrier(1) Hydraulic Crash Rated Telescopic Rising Bollard(1)

Hydraulic Crash Rated Telescopic Rising Bollard(1)

Product Reviews

Read all reviewsSadat Hossain

From Gazipur on 30th Jun, 2022Submit your review

Your email address will not be published. Required fields are markedAdd Images & Videos to your review

Allowed file types: jpg, gif, png,mp4,avi max total size of files: 100MB, max number of files: 8!